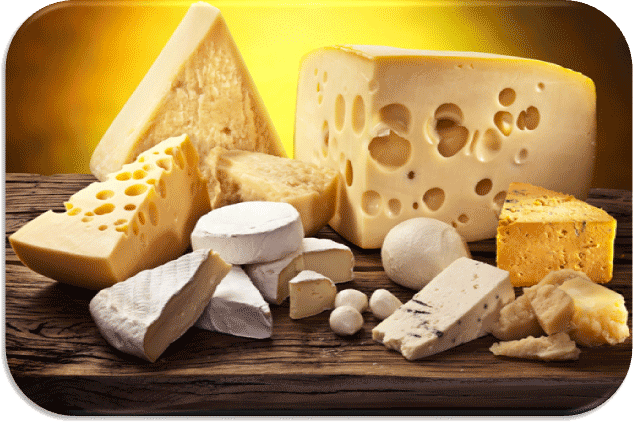

Cheese: how it is made

An extract of the original document…

What it is

Cheese is the product obtained by coagulation from milk thanks to the action of rennet or other coagulants. Cheese is the result of the concentration of certain elements present in milk. Fats and proteins are concentrated, whereas sugars and mineral salts are distributed in the water content. The remaining liquid is called whey.

How it is made

- curd formation

The cheese-making process generally consists in adding rennet to raw milk. The rennet is usually of animal origin and is made up of gastric juices from the stomach of mammals (cows, sheep, goats). In the past vegetable juices were also used, from the fig tree, artichoke or thistle.

Three kinds of rennet are available commercially: in liquid, powdered or paste form.

Once the rennet is added, the casein changes from a soluble state to a gelatinous state; this creates a solid network that encases the fat globules. Thus the solid curd and the liquid whey are formed.

- curd breaking and separating

Separating means removing the whey from the curd. This process is begun by breaking up the curd mechanically. When the curd has reached a certain consistency it is cut and broken into smaller curds. It is done manually, sometimes with a dry stick.

- cooking, molding and pressing

The broken up curds are separated from the whey and put into the molds where they will begin to take shape and start the ageing process. If the curds are not heated and are kept at a temperature of no more than 41°C, we have what is called a raw cheese.

The pressing is done directly in the molds, either manually using the hands or mechanically with special instruments.

- pulling and salting

In order to have a stringy cheese, the curds are left to soak in the whey at a temperature of 100°C for several hours. Then the cheese becomes elastic and stringy and is hand processed, pulled and reduced to filaments then shaped in various ways. Thus one obtains mozzarella, provola or caciocavallo.

The salting is done at the end of the processing, when the cheese is still fresh. Regular kitchen salt is used. The function of the salt is to drain out the remaining whey and to help form the rind; it also prevents mould and mildew and makes the cheese tasty. The salting may be done dry, in brine or with a paste.

- ageing

The ageing of the cheese completes the ripening process. A cheese is ripe when it has reached the desired consistency and appearance as well as the aroma and particular taste which distinguish it. There are various ageing times, from just a few days for fresh cheeses to several years for cooked cheeses.

During the ageing process the cheese breathes and dries, the texture hardens and the color darkens. Sometimes cavities (holes) appear as a result of the formation of carbon dioxide.

To be continued…